Rapid Tooling

DFM Reports and Mold Flow Analysis

Low Cost Fast Delivery

One stop Tooling Solutions

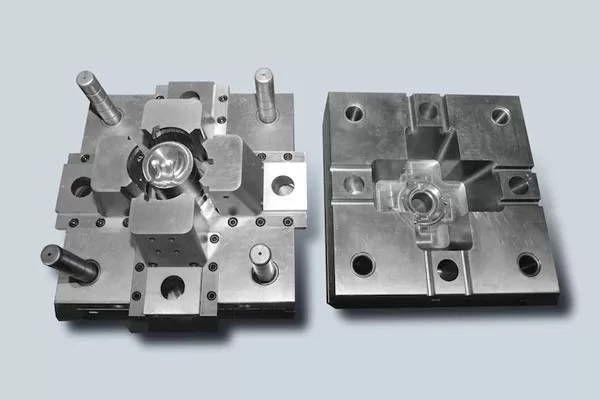

Precision Rapid Tooling Services

At Yumar mold, we offer a wide range of manufacturing services and solutions for all your rapid tooling needs. From your design concept to creation, all of your designs and ideas are created efficiently and securely in our shop, it’s a one-stop for everything providing you with the ultimate class and convenience. Our center of production is quite spacious giving our engineering and design team ample space to work on your project in an efficient and free manner. Our production and sales team work hand in hand thus ensuring that the final end-products match the original designs and ideas. Our rapid tooling services are tailor-made to provide you with quality injection molded parts within the shortest time possible. Additionally, the confirmation process of all your designs will be fastened giving you a picture of the final injection molded parts using your preferred material. Learn more about our plastic injection molding services. Rapid tooling is one of the quickest and fastest ways of production compared to the tooling process, this is partly attributed to the efficient ways in which the CAD designs are produced. Additionally, rapid tooling also involves smaller volumes making it an effective and efficient way. After we receive the CAD files, we will send you the samples within 15-days. This is just a rough estimate it can even be shorter than the set time limit, the efficiency and effectiveness of the design tool can result in larger production cycles using the same tool which will not only reduce production cost but also improve on efficiencies.

Common Types of Rapid Tooling

Aluminum Mold Tooling and Steel Mold Tooling

The enduring debate between aluminum and steel as the superior material in terms of longevity and cost-effectiveness remains a perennial topic. At our company, we take pride in delivering top-notch services to our clients, which is why we aim to shed light on this ongoing discussion. With our extensive experience, we’ve observed that steel has traditionally been the preferred choice for most rapid tooling projects due to its durability. However, recent fluctuations in steel prices have prompted a shift in favor of aluminum. Apart from its cost advantage, aluminum boasts quicker production times, spearheading a revolution in rapid tooling. At Yumar mold, we stand at the forefront of this evolution. Below, we present a concise comparison between these two remarkable materials.

Aluminum Mold Tooling

- Suitable for complex parts

- Large pool for surface finish options

- Easy to modify

- Less flash and over-weld

- Cost-effective and long-lasting

Steel Mold Tooling

- Faster production times

- Easy to store and move

- Low cost of production

- Heat transfer faster

- Light weight

Benefits of Rapid Tooling

1. Faster Time to Market

In conventional tooling method, multiple manufacturing processes and techniques might be involved in product development cycle. This may increase the time spending on each step and extend the time from design turning into a real product. Rapid Tooling involves fewer steps than conventional tooling method. Rapid Tooling enables speeding up the whole process. The faster you can get through the prototyping and molding process, the sooner you can finalize your design and get it into the customers’ hand.

2. Lower Cost

The longer time spending on product development cycle, the greater the cost will be. The Rapid Tooling advantage of speed could save your business money over time.

3. Variety of Material Grades

Rapid Tooling allows you to use the actual production grades of material. You can use Rapid Tooling to fabricate custom mold quickly. You can then produce as many prototypes from this mold as you can, creating parts with different material grades and test on their properties. This will allow you to have a clearer picture on which material grade performs best in real world application and allow you to make the correct material selection before launching the new product in the market.

4. Designs and Functionality Testing

Rapid Tooling allows the mold to be fabricated in a short timeframe. Hence, this provides more freedom to test out the new ideas and make design adjustments. The parts can be mechanical tested such as impact and stress testing to explore the design flaws before production. This will massively prevent a lot of issues arisen during the future high volume production stage.

5. Process Parameter Testing

Rapid Tooling can also be used to test the process parameter during production stage. For example, different injection speed and mold temperature for injection molding process will affect the part quality. In this way, the engineers and designers could have more measure control on the final part.

Choosing the Best Rapid Tooling Process

Although there are a lot of advantages in Rapid Tooling process, Rapid Tooling is not always suited for all projects. One of the drawbacks of Rapid Tooling is precision. Rapid Tooling might not be as precise as conventional tooling. However, it becomes less concern nowadays thanks to the technology advancement in the 3D printing and CNC machining technology, which shows great improvement in precision and accuracy.

Before starting your project, always consult with an experienced manufacturer your requirement and expectation. Main factors that will decide whether Rapid Tooling process is appropriate for you project are as following:

- Project Budget

- Product Development Timeframe

- Part Specification & Tolerances

- Multiple Materials to be tested?

- Mold or Die to be used for large-scale production?

The upfront clear and well communication with manufacturer will help manufacturer determine which process is your best option. It will save you a lot of time and fortune with relatively ease in your project from prototyping stage to manufacturing stage.