High-Quality Mold Designing Service For You

Yumar always provide professional engineering solutions to meet the your specifications as you expected. 20+ years mold designing experience can be the reason to trust us.

Professional and efficient mold design team

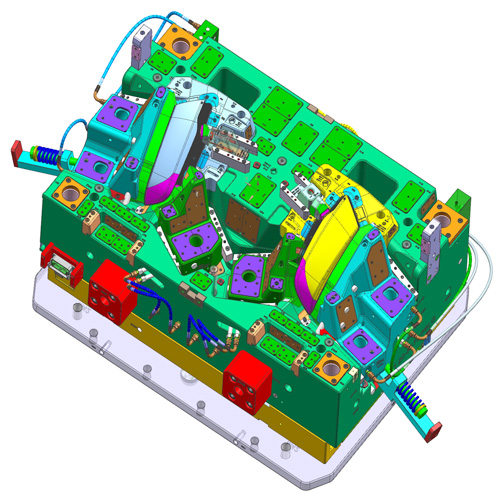

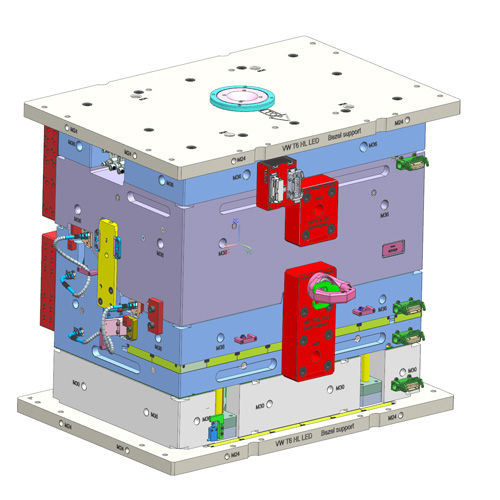

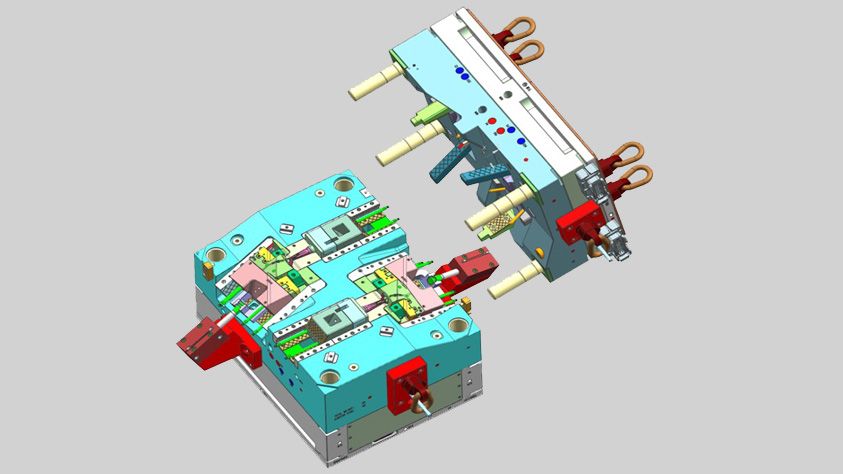

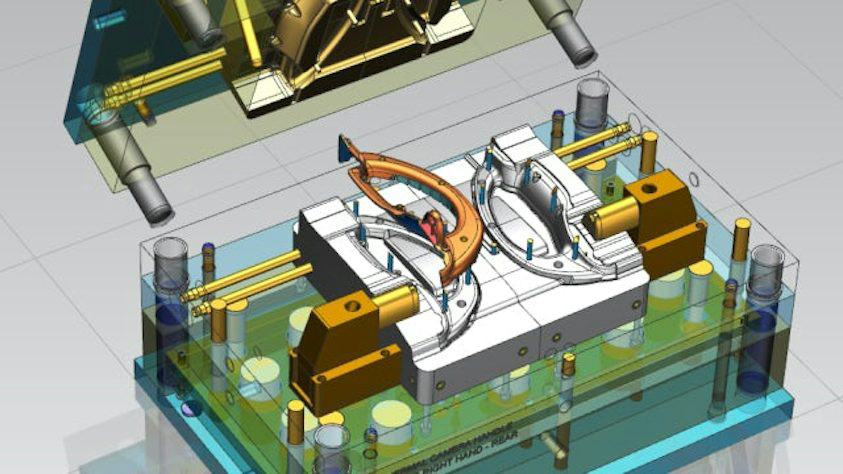

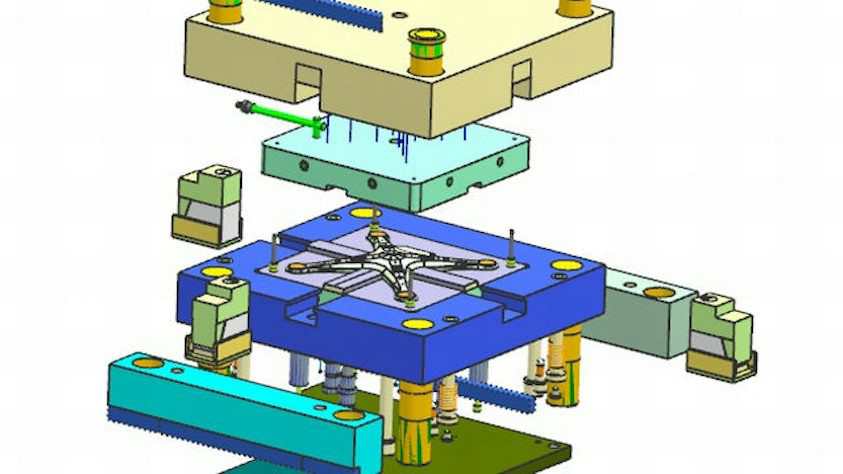

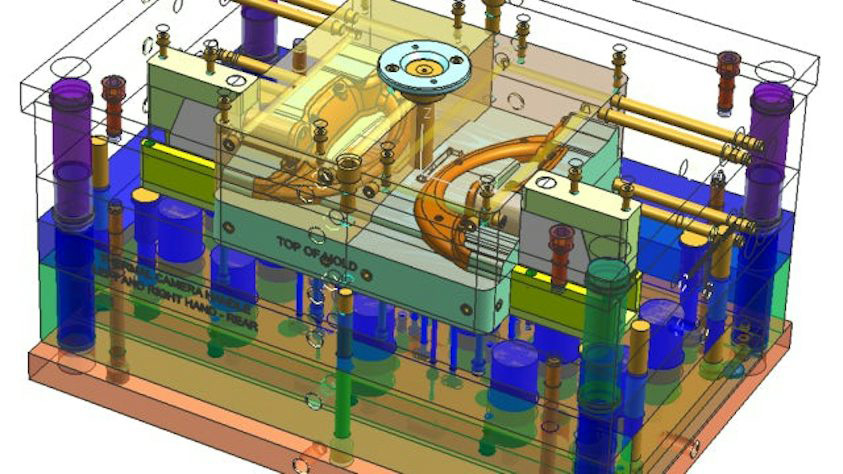

Our company apply the advanced mold design and analysis software to simulate the design scheme evaluation and optimize processing, more rationalization, digitization to meet the customers’ higher demand for mold.

● Mold designer:6 people

● Project Engineer:3 people

● Process Engineer:3 people

● Monthly capability:40 sets

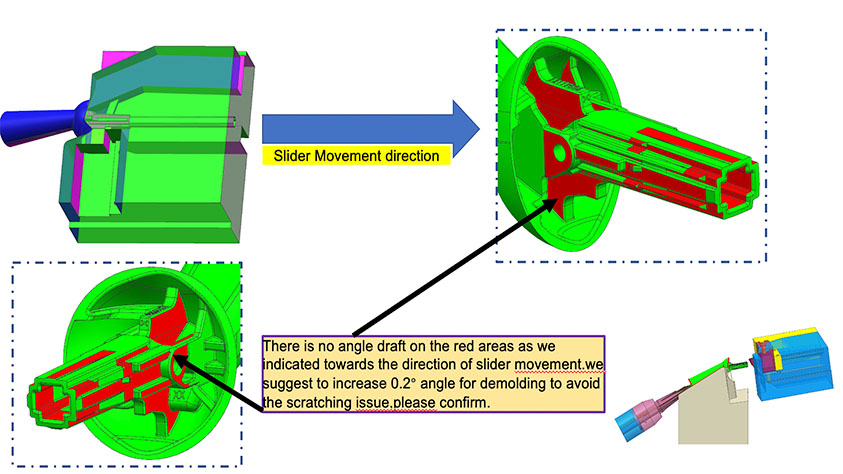

■ We share the experience and lesson learnt to avoid the same issue happen again.

■ Always figure out the root cause and come up with the solution.

■ All issues will be recorded in manual instruction to achieve continuous improvement.

■ We hold the regular internal meetings to learn from the failure case and take prevention measures.

What Are Injection Mold Design?

Mold design process

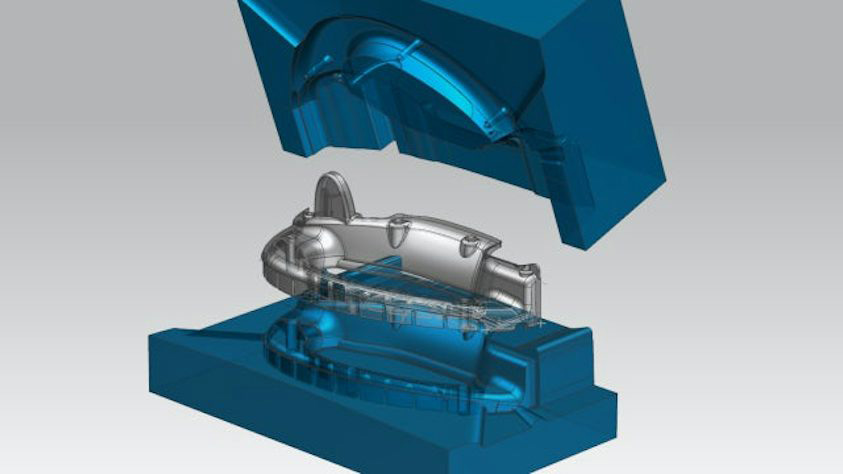

Step 01: Product Analysis

Step 02: MoldFlow Simulation

Step 03: Mold Structure

Step 04: Design Validation

Step 05: Dimension Analysis

6.Design change and propagation control

High Quality Mold Begin With The Excellent Design

The performance of the mold largely depends on the maturity of the design.

Our experienced designer are the mainly factor to the quanlity of Yumar molds.

The mission of our designing team is to simplify the mold structure and cost less

without any compromise on mold quanlity.Always thinking out of the box to meet

your request to mass production and make the molds easy for maintanence

We can even provide the part analysis report during part development phrase to

achieve feasible mold design,it will be helpful to save your part development time

and costs