Plastic Injection Overmolding Manufacturing

Discover the Ideal Solutions for Your Plastic Injection Overolding Project: Achieve Excellence with Optimal Solutions

What is Overmolding?

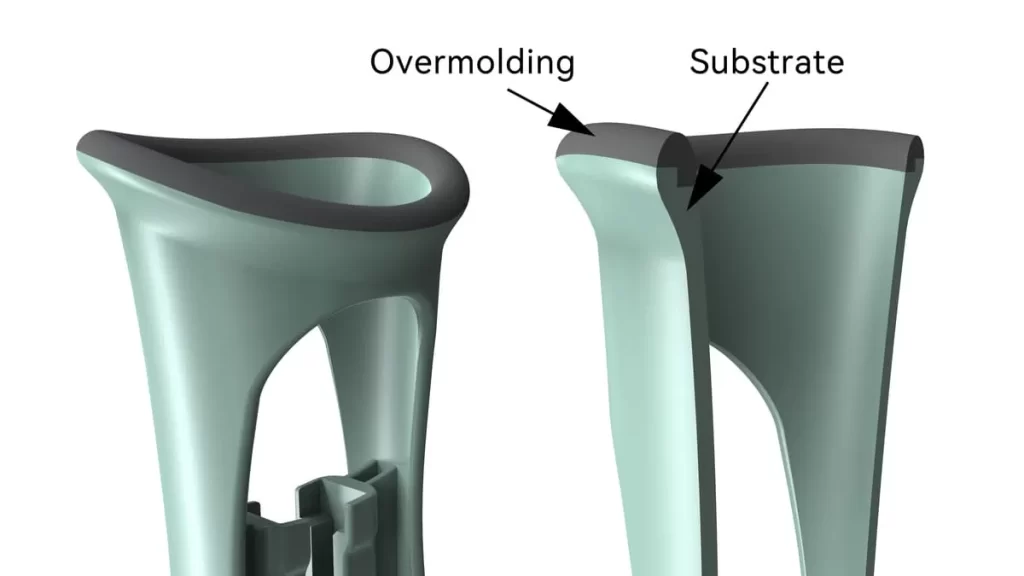

Overmolding is an injection molding process where you mold one material over top of another material or substrate. The first material is usually made of a different material or has a different shape than the second material. Overmolding is used in many industries including medical devices, automotive, aerospace, and consumer products.

To overmold, you first mold or make the first part. Then you mold the second material over top of the first part. The second material can be a different plastic, rubber, or other material that gives the part special properties like flexibility, durability, or looks.

How Does Overmolding Work?

Overmolding is a tricky process that has a bunch of steps and needs you to plan and do it right. Here’s a quick look at how overmolding works:

1. Design and Prototype:Designers create a 3D model of the main part and the other material. They make prototypes to test the design and make sure it meets the required specs.

2. Tooling:Tooling is made for both the main part and the other material. Tooling includes molds, and other equipment needed for the molding process.

3. Main Part Production: The main part is made using the main tooling. The main part is usually made of a hard material, like hard plastic (PP, ABS, PA, PC, etc).

4. Overmolding Process: The other material is injected into the mold, which has the main part. The other material flows around the main part, making a strong bond. The other material is designed to fit the shape of the main part.

5. Cooling and Ejection: The mold is cooled for the other material to solidify. Then the mold is ejected, and the overmolded part is removed.

6. Finishing: We check the overmolded part to make sure it’s good to go. We trim off any extra plastic, clean it up, and get it ready for the next step.

What are the Benefits of Overmolding?

Overmolding is great because:

Better Chemical Resistance: Overmolding can be used to make the primary part more resistant to chemicals, so it doesn’t get all corroded and messed up.

Added Functionality: Overmolding can be used to add new features or functionality to the primary part, thereby increasing its utility and value.

Simplified Assembly: Overmolding can help you avoid assembly by combining multiple parts into one, which makes manufacturing easier.

Better Performance: Overmolding can be used to make the primary part better by adding new materials or properties that make it work better.

Make it Look Good: Overmolding can make the main part look better. It makes it look nice.

Lose Weight: Overmolding can help you lose weight. It makes your main part lighter, but still strong and tough. It makes it easier to carry and handle.

Better Thermal Resistance: Overmolding can be used to make the primary part more resistant to heat, so it won’t get too hot or cold.

Stronger and Tougher: Overmolding can make your part stronger and tougher, so it lasts longer and performs better.

Better Electrical Insulation: Overmolding can be used to improve the electrical insulation of the main part, which helps protect it from electrical shock and damage.

Better Looking: Overmolding can make the main part look better. It can be made to look more attractive.

What are the Applications of Overmolding?

Overmolding is a versatile manufacturing process that can be used to create complex parts with unique properties and functionality, making it applicable to a wide range of industries.

Handware tools: Overmolding can be used to make hand tools like wrenches, pliers, and screwdrivers, knives, saw blades, and drill bits tougher and easier to hold.

Medical Devices: Overmolding is used in medical devices like syringes, needles, and implantable devices, where precision and accuracy are crucial.

Automotive: Overmolding is used in car stuff like dashboards, door handles, and trim components, where you need them to last and work good.

Industrial Equipment: Overmolding is used in industrial equipment like machines, pumps, and valves where you need them to be tough and work good.

Consumer Products: Overmolding is used in consumer products like toys, appliances, and electronics, where looks and how it works are important.